In the complex world of construction management, where projects require careful coordination and efficient resource allocation, implementing the right project management methodology is crucial. One such methodology that has gained popularity in recent years is Kanban. Kanban, which originated in the manufacturing industry in Japan, has proven to be effective in improving productivity and optimizing workflow. This article will delve into the basics of Kanban, discuss its benefits in construction management, outline the steps to implement it, address the challenges that may arise, and explore how to measure its success in construction management.

Understanding the Basics of Kanban

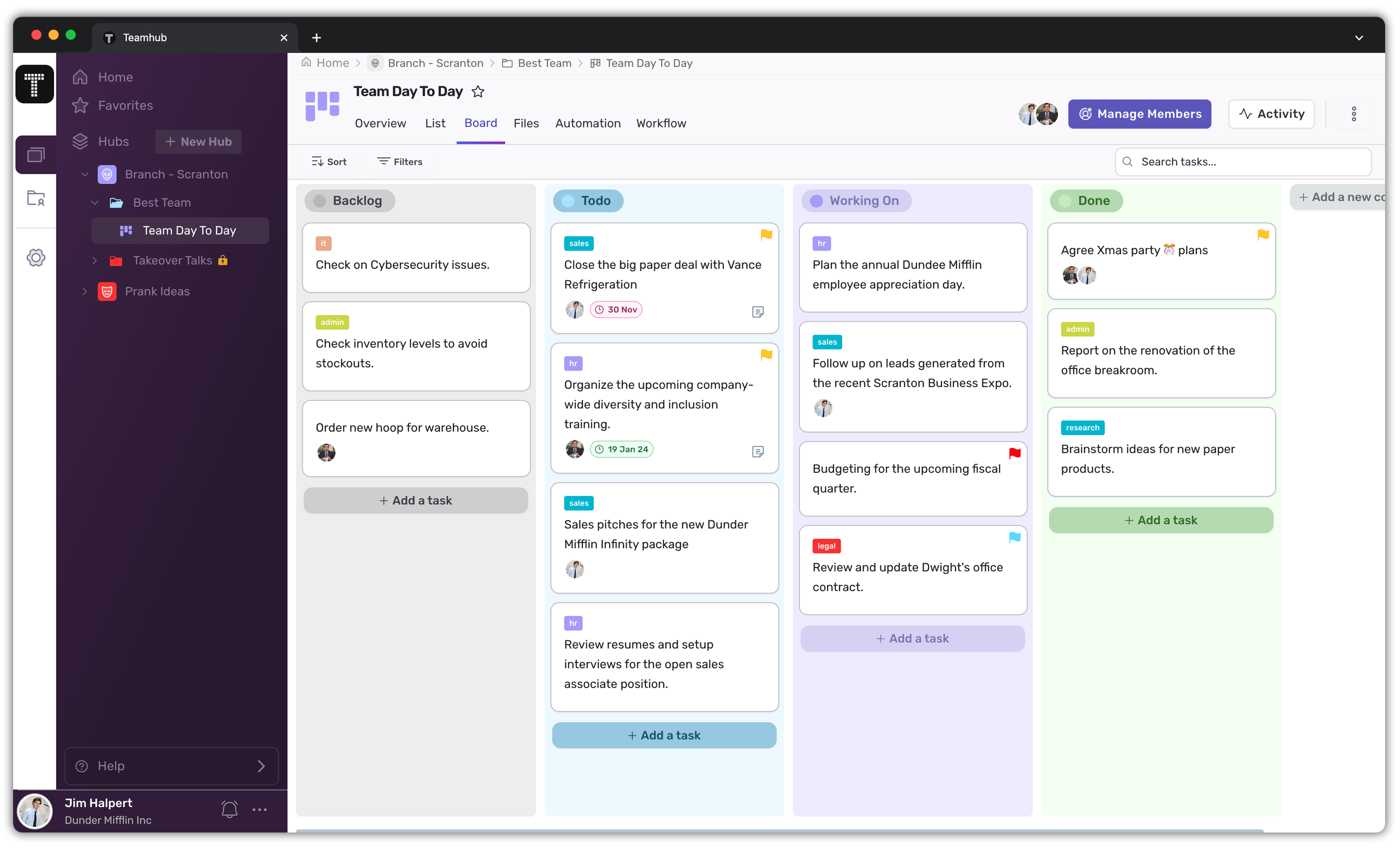

Kanban is a visual project management method that aims to facilitate the flow of work by visualizing the workflow, limiting work in progress, and fostering continuous improvement. By employing a Kanban board, which typically consists of columns representing different stages of work and cards representing tasks or work items, teams can gain clarity and transparency about project status and progress. The core principles of Kanban can be summarized as follows:

The Principles of Kanban

The first principle of Kanban is to visualize the workflow. This involves mapping out the steps involved in completing a project and representing them visually on a Kanban board. By doing so, everyone on the team can have a clear understanding of the work to be done and its current status.

The second principle is to limit work in progress (WIP). This means setting a maximum limit on the number of tasks or work items that can be in progress at any given time. By doing so, teams can avoid overburdening themselves and ensure that the focus remains on completing tasks before taking on new ones.

The third principle is to manage flow and make adjustments. Kanban encourages teams to continuously monitor and analyze the flow of work, identifying bottlenecks or areas for improvement. By making adjustments based on this analysis, teams can optimize their workflow and maintain a steady pace of progress.

Unlock Efficiency with Teamhub

The Benefits of Kanban in Construction Management

Implementing Kanban in construction management brings forth numerous benefits. First and foremost, it enables improved communication and collaboration among team members. With a visual representation of the workflow and clear task assignments, teams can work together more effectively, minimizing misunderstandings and promoting a sense of shared responsibility.

Furthermore, Kanban enhances project visibility and transparency. By having a centralized Kanban board, stakeholders can easily track the progress of a project and stay informed about any updates or changes. This visibility reduces the likelihood of misalignment or delays and fosters a culture of accountability.

In addition, Kanban helps in optimizing resource allocation and minimizing waste. By limiting WIP, teams can align their resources with actual capacity, reducing the likelihood of overworking and improving efficiency. Moreover, by continuously analyzing the flow of work, teams can identify and address areas of waste, such as unnecessary waiting or rework, leading to cost savings and improved productivity.

Another benefit of Kanban in construction management is its adaptability to changing project requirements. Construction projects often involve unexpected changes or variations, and Kanban provides a flexible framework to accommodate these changes. By visualizing the workflow and having a clear understanding of the current status of tasks, teams can easily adapt and reprioritize work as needed.

Additionally, Kanban promotes a culture of continuous improvement. By regularly analyzing the flow of work and identifying areas for improvement, teams can implement changes and experiment with new approaches to enhance productivity and efficiency. This focus on continuous improvement fosters a learning mindset within the team and encourages innovation.

Moreover, Kanban in construction management can help in managing dependencies and coordinating different teams or subcontractors involved in a project. By visualizing the workflow and identifying dependencies between tasks, teams can proactively address any potential bottlenecks or coordination challenges, ensuring smooth progress and timely completion of the project.

Lastly, Kanban provides a transparent and data-driven approach to project management. By tracking and analyzing the flow of work, teams can gather valuable data and metrics that can be used for performance evaluation, process optimization, and informed decision-making. This data-driven approach enables teams to make evidence-based decisions and continuously improve their project management practices.

Steps to Implement Kanban in Construction Management

Implementing Kanban in construction management involves a series of steps that are essential for a successful implementation. These steps can be summarized as follows:

Identifying the Workflow

The first step is to identify and define the workflow of the project. This involves understanding the various stages and sub-stages involved in completing the project. By breaking down the project into manageable components, teams can gain a clearer picture of the work that needs to be done and how it flows.

For example, in a construction project, the workflow may include stages such as site preparation, foundation construction, structural framing, electrical and plumbing installation, interior finishing, and final inspection. Each of these stages can be further divided into sub-stages, such as obtaining permits, ordering materials, and scheduling inspections.

Visualizing the Workflow

Once the workflow is identified, the next step is to visualize it on a Kanban board. This can be done by creating columns representing the different stages of work and using cards or sticky notes to represent tasks or work items. Each task should be clearly defined and assigned to a specific team member.

For instance, on the Kanban board, the column for the site preparation stage may include cards for tasks such as clearing the site, leveling the ground, and installing temporary fencing. Each card will have details about the task, including its priority, estimated time to complete, and the team member responsible for its execution.

Setting Work in Progress Limits

After visualizing the workflow, it is crucial to set work in progress (WIP) limits for each column on the Kanban board. These limits should be determined based on the team’s capacity and the project’s requirements. By limiting WIP, teams can prevent overloading themselves and maintain a steady pace of progress.

For example, if the electrical and plumbing installation stage has a WIP limit of two tasks, it means that the team can only work on two tasks at a time in that stage. This helps prevent bottlenecks and ensures that tasks are completed in a timely manner.

Managing Flow and Making Adjustments

Once the Kanban board is set up and WIP limits are defined, teams can start managing the flow of work. By regularly reviewing and analyzing the board, teams can identify bottlenecks or areas of improvement. Adjustments can be made to optimize the workflow and ensure a smooth flow of work from start to finish.

For instance, if the team notices that a particular stage consistently has a high number of tasks in progress, they may need to allocate more resources to that stage or re-evaluate the WIP limit. Similarly, if a stage has a consistently low number of tasks, it may indicate that the team can take on more work in that area.

Regular communication and collaboration among team members are essential for managing flow and making adjustments. By discussing challenges, sharing insights, and brainstorming solutions, the team can continuously improve the implementation of Kanban in construction management.

Overcoming Challenges in Kanban Implementation

Implementing Kanban in construction management may encounter challenges, such as resistance to change, training and skill development, and ensuring continuous improvement. These challenges can be addressed through careful planning and proactive measures.

When it comes to implementing Kanban, it is essential to understand the potential hurdles that may arise and have strategies in place to overcome them. Let’s delve deeper into each challenge and explore effective solutions:

Resistance to Change

Resistance to change is a common challenge in any organizational transformation. People are often comfortable with the status quo and may be hesitant to embrace new methodologies. To overcome this challenge, it is crucial to communicate the benefits of Kanban and involve employees in the decision-making process.

One effective strategy is to hold open forums where employees can voice their concerns and ask questions. This allows for a transparent and inclusive environment, fostering a sense of ownership and involvement. Additionally, providing training and support during the transition period can help alleviate concerns and boost adoption. By addressing individual concerns and demonstrating the positive impact of Kanban, resistance can be minimized.

Training and Skill Development

To effectively implement Kanban, teams may require training and skill development in its principles and tools. While Kanban is relatively straightforward, it is essential to ensure that all team members have a solid understanding of its concepts and how to apply them.

Providing comprehensive training sessions and coaching can equip team members with the necessary knowledge and skills to utilize Kanban effectively, ensuring a successful implementation. These training sessions can cover topics such as visualizing workflow, setting work-in-progress limits, and using metrics to measure performance. By investing in training and skill development, teams can confidently embrace Kanban and maximize its benefits.

Ensuring Continuous Improvement

Kanban is a dynamic methodology that thrives on continuous improvement. It is crucial to create an environment that encourages experimentation and learning. Teams should foster a culture where everyone feels comfortable providing feedback and suggesting improvements.

Regular review meetings and retrospectives can be instrumental in identifying areas for improvement and driving ongoing enhancements. These meetings provide an opportunity to reflect on the effectiveness of the Kanban implementation, identify bottlenecks, and brainstorm solutions. By continuously seeking ways to improve, teams can optimize their workflow and achieve higher levels of efficiency and productivity.

In conclusion, implementing Kanban in construction management may present challenges, but with careful planning and proactive measures, these challenges can be overcome. By addressing resistance to change, providing comprehensive training, and fostering a culture of continuous improvement, organizations can successfully implement Kanban and reap its numerous benefits.

Measuring the Success of Kanban Implementation

Measuring the success of Kanban implementation is crucial for evaluating its effectiveness and identifying areas for further enhancement. The following are key methods to measure the success of Kanban in construction management:

Key Performance Indicators for Kanban

Implementing Kanban allows for the tracking of key performance indicators (KPIs) that provide insights into project performance. KPIs such as lead time, cycle time, and throughput can help measure the efficiency and effectiveness of the Kanban system. Regularly monitoring these KPIs can help identify areas for improvement.

Regular Review and Feedback

Regular review and feedback sessions are essential to assess the impact of Kanban implementation. By seeking input from team members and stakeholders, teams can gather data on the effectiveness of Kanban in terms of communication, coordination, and productivity. This feedback can then be used to make adjustments and drive continuous improvement.

Long-Term Benefits of Kanban in Construction Management

The successful implementation of Kanban in construction management can bring forth long-term benefits. Improved productivity, enhanced collaboration, and optimized resource allocation are just a few of the advantages teams can expect to reap. Additionally, Kanban promotes a culture of continuous improvement and empowers teams to overcome challenges and adapt to changing project requirements.

In conclusion, implementing Kanban in construction management can significantly enhance project management practices, resulting in improved efficiency, collaboration, and resource optimization. By understanding the basics of Kanban, following the steps to implement it, addressing challenges, and measuring its success, construction management teams can leverage this powerful methodology to achieve project success and deliver projects with speed and quality.