Quality assurance is a crucial aspect of any organizational process. It ensures that products and services meet the required standards and customer expectations. In this article, we will delve into the world of quality assurance formulas, understanding the basics, decoding complex formulas, and overcoming challenges.

Understanding the Basics of Quality Assurance

Quality assurance, often abbreviated as QA, refers to the systematic process of checking and verifying whether a product or service meets specified requirements. It ensures that organizations deliver consistent, high-quality results and minimize the risk of defects or errors. Quality assurance plays a vital role in maintaining customer satisfaction and brand reputation.

Quality assurance involves a comprehensive set of activities designed to guarantee the quality of a product or service. It encompasses quality planning, quality control, and quality improvement. By implementing quality assurance practices, organizations can ensure that their products or services meet or exceed customer expectations.

Definition and Importance of Quality Assurance

Quality assurance, at its core, involves a set of activities designed to guarantee the quality of a product or service. It encompasses quality planning, quality control, and quality improvement. The main importance of quality assurance lies in its ability to provide confidence to customers that they are receiving reliable and satisfactory products or services.

Quality assurance is essential for organizations to build trust and maintain customer loyalty. When customers have confidence in the quality of a product or service, they are more likely to make repeat purchases and recommend the organization to others. This, in turn, leads to increased customer satisfaction and brand reputation.

Key Components of Quality Assurance

Quality assurance comprises several key components that work hand in hand to ensure product or service excellence. These components include:

- Quality standards and guidelines: Quality assurance relies on established standards and guidelines to define the expected level of quality for a product or service. These standards serve as benchmarks for organizations to measure their performance and identify areas for improvement.

- Process documentation: Documentation is a crucial aspect of quality assurance. It involves capturing and recording the processes and procedures followed in the production or delivery of a product or service. This documentation serves as a reference for employees, ensuring consistency and accuracy in their work.

- Training and development programs: Quality assurance requires a skilled and knowledgeable workforce. Training and development programs play a vital role in equipping employees with the necessary skills and knowledge to perform their roles effectively. These programs help employees understand the importance of quality and provide them with the tools and techniques to ensure it.

- Quality audits and inspections: Regular audits and inspections are conducted to assess the effectiveness of quality assurance practices. These audits and inspections help identify any deviations from established standards and guidelines, allowing organizations to take corrective actions promptly.

- Corrective and preventive actions: When deviations or defects are identified, corrective and preventive actions are implemented to address the root causes and prevent recurrence. These actions can include process improvements, employee training, or changes in quality control measures.

These components collectively contribute to the successful implementation of quality assurance within an organization. By integrating these components into their operations, organizations can ensure that their products or services consistently meet or exceed customer expectations, leading to improved customer satisfaction and business success.

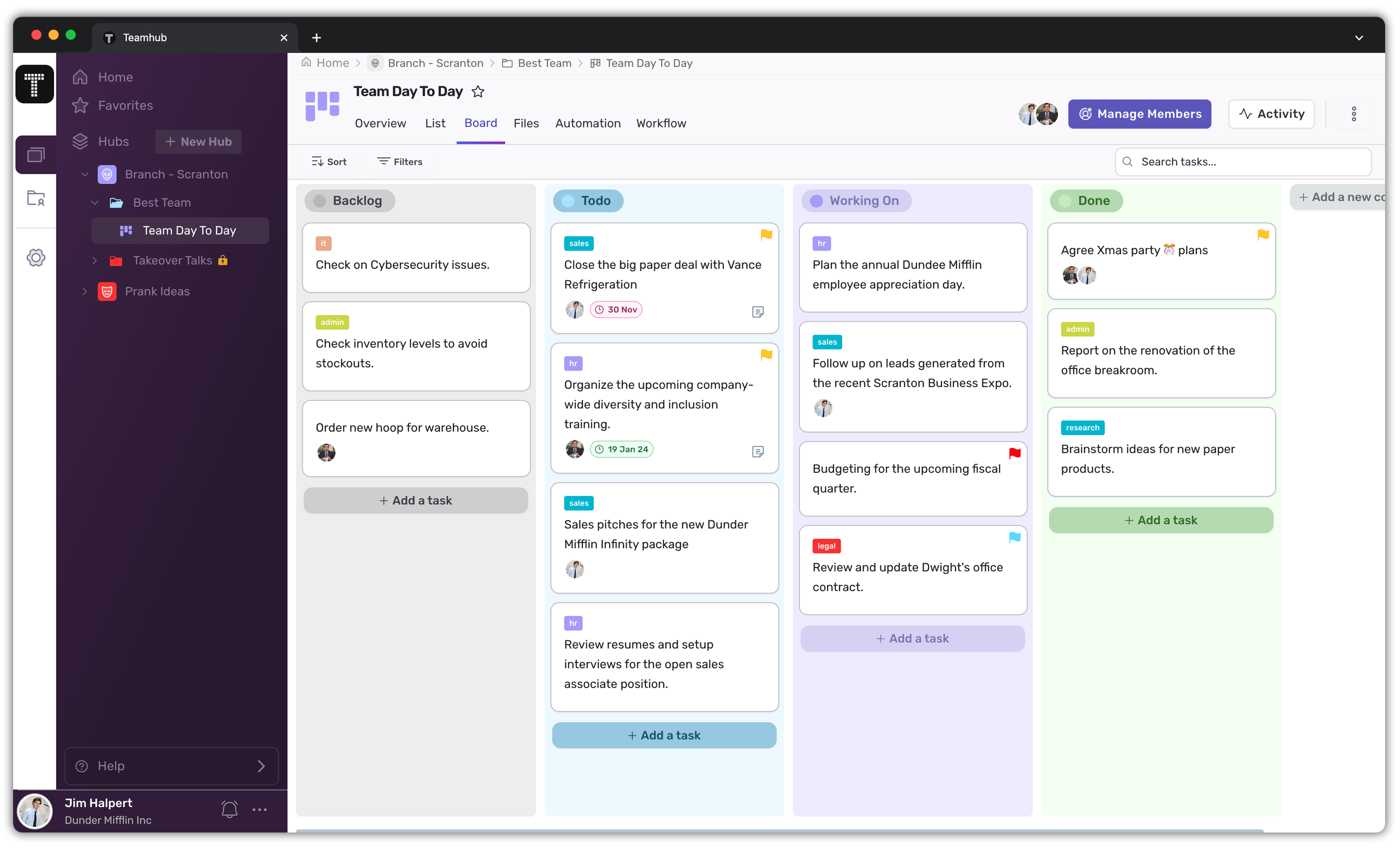

Unlock Efficiency with Teamhub

Diving into Quality Assurance Formulas

Formulas are an integral part of quality assurance as they provide a standardized approach to measuring and analyzing quality-related metrics. They enable organizations to quantify the performance of processes, products, and services, facilitating data-driven decision-making.

Quality assurance professionals rely on formulas to measure various factors that are indicative of quality. These formulas help in assessing defect rates, failure rates, reliability, and efficiency. By utilizing formulas, organizations gain a clear understanding of their current quality levels and identify areas for improvement.

The Role of Formulas in Quality Assurance

Formulas serve as a means to calculate specific metrics that are crucial in evaluating quality. They provide a structured framework for measuring and analyzing data, enabling organizations to make informed decisions. By utilizing formulas, quality assurance professionals can objectively assess the performance of processes, products, and services.

Formulas are particularly useful in quality assurance as they allow for consistent measurement and comparison. They provide a common language and methodology for evaluating quality-related metrics, ensuring that organizations can effectively communicate and collaborate on quality improvement initiatives.

Commonly Used Quality Assurance Formulas

Here, we will explore some commonly used quality assurance formulas:

Defect Rate Formula: Defect Rate = (Number of Defects / Total Units Tested) * 100

The defect rate formula is widely used in quality assurance to measure the proportion of defects in a given sample. It helps organizations assess the quality of their products or services by calculating the percentage of defects in relation to the total units tested. This formula provides valuable insights into the overall quality performance and helps identify areas for improvement.

Failure Rate Formula: Failure Rate = (Number of Failures / Total Operating Time)

The failure rate formula is essential in quality assurance for evaluating the reliability of products or services. It measures the rate at which failures occur during a specified period, considering the total operating time. By calculating the failure rate, organizations can identify potential weaknesses and take proactive measures to improve reliability.

Process Capability Index Formula: Process Capability Index = (Upper Specification Limit – Lower Specification Limit) / (6 * Standard Deviation)

The process capability index formula is used to assess the capability of a process to meet specified requirements. It compares the spread of process variation to the tolerance limits defined by upper and lower specification limits. By calculating the process capability index, organizations can determine if their processes are capable of consistently producing products or services within the desired specifications.

These formulas are just a glimpse into the extensive range of calculations that quality assurance professionals employ to ensure product or service excellence. By utilizing a wide array of formulas, organizations can gain comprehensive insights into their quality performance and drive continuous improvement.

Decoding Quality Assurance Formulas

Interpreting quality assurance formulas involves understanding the insights they provide and how they relate to the overall quality objectives of an organization. It is essential to consider the context, industry standards, and specific requirements when deciphering the meaning behind the calculated metrics.

Quality assurance formulas serve as a vital tool for organizations to measure and evaluate their performance. By analyzing these formulas, businesses can gain valuable insights into their processes and identify areas for improvement. These formulas provide a quantitative foundation for assessing and enhancing operations.

Interpretation of Quality Assurance Formulas

Interpreting quality assurance formulas allows organizations to gain valuable insights into their performance and potential areas of improvement. For example, a high defect rate may indicate gaps in the manufacturing process, necessitating corrective actions to enhance product quality.

When analyzing quality assurance formulas, it is crucial to consider the specific context and objectives of the organization. Each formula provides a unique perspective on quality, and interpreting them requires a comprehensive understanding of the underlying principles and industry standards.

Furthermore, quality assurance formulas can help organizations identify trends and patterns in their data. By analyzing these patterns, businesses can make informed decisions and implement strategies to optimize their processes and achieve higher levels of quality.

Application of Quality Assurance Formulas

Quality assurance formulas find application across various industries and sectors. From manufacturing and software development to healthcare and finance, quality assurance calculations provide a quantitative foundation for assessing and improving operations.

In the manufacturing industry, quality assurance formulas are used to measure defect rates, production efficiency, and overall product quality. By analyzing these metrics, organizations can identify areas for improvement and implement strategies to enhance their manufacturing processes.

In the software development field, quality assurance formulas play a crucial role in assessing the reliability, functionality, and performance of software applications. These formulas help identify bugs, errors, and performance bottlenecks, allowing developers to refine their code and deliver high-quality software to end-users.

Healthcare organizations utilize quality assurance formulas to evaluate patient outcomes, infection rates, and adherence to medical protocols. By analyzing these metrics, healthcare providers can identify areas for improvement and implement strategies to enhance patient care and safety.

Similarly, in the finance industry, quality assurance formulas are used to assess the accuracy and reliability of financial statements, ensuring compliance with regulatory standards. These formulas help organizations identify potential errors or discrepancies in financial data, allowing them to maintain transparency and trust with stakeholders.

Overall, quality assurance formulas have broad applications across various industries, enabling organizations to measure, evaluate, and improve their operations. By understanding and interpreting these formulas, businesses can make data-driven decisions and achieve higher levels of quality and performance.

Advanced Concepts in Quality Assurance Formulas

As organizations strive for continuous improvement, quality assurance formulas are constantly evolving to meet the demands of complex processes and systems. Advanced concepts push the boundaries of quality assurance, enabling organizations to delve deeper into their quality metrics.

Complex Quality Assurance Formulas

Complex quality assurance formulas involve intricate calculations and statistical models to analyze quality-related data. These formulas allow for a more comprehensive evaluation of processes and products, aiming to optimize performance and minimize defects.

The Future of Quality Assurance Formulas

As technology continues to advance, the future of quality assurance formulas lies in automation and artificial intelligence. Leveraging machine learning algorithms and predictive analytics, organizations can gain real-time insights and predictive capabilities to optimize quality assurance processes.

Overcoming Challenges in Quality Assurance Formulas

While quality assurance formulas provide valuable insights, they are not without challenges. Addressing these challenges allows organizations to maximize the benefits of quality assurance.

Common Issues with Quality Assurance Formulas

Some common issues that organizations face in quality assurance formulas include:

- Data accuracy and integrity

- Interpreting complex formulas

- Adapting formulas to unique product/service characteristics

By acknowledging these challenges, organizations can take proactive measures to mitigate risks and improve the accuracy of their quality assurance processes.

Solutions for Quality Assurance Formula Challenges

Organizations can overcome quality assurance formula challenges by implementing various solutions:

- Implementing robust data collection and validation processes

- Investing in training programs to enhance formula interpretation skills

- Customizing formulas to align with specific product or service requirements

These solutions empower organizations to optimize the effectiveness of quality assurance formulas and increase overall operational quality.

Quality assurance formulas play a vital role in ensuring the consistency and reliability of products and services. By understanding the basics, decoding complex formulas, and addressing challenges, organizations can leverage quality assurance formulas to achieve and surpass customer expectations, thereby driving success in today’s competitive market.

0 thoughts on “Quality Assurance Formulas Explained”