In today’s competitive business environment, it is essential for organizations to establish effective supplier performance metrics. Supplier performance metrics are measurements that help assess the performance of suppliers and their ability to meet the requirements and expectations of the buying organization. By implementing these metrics, businesses can gain valuable insights into supplier performance, identify areas for improvement, and drive better outcomes.

Understanding the Importance of Supplier Performance Metrics

When it comes to supplier management, understanding the importance of supplier performance metrics is crucial. These metrics provide objective criteria for evaluating and comparing suppliers based on their performance in specific areas. By having a clear understanding of supplier performance, organizations can make well-informed decisions regarding supplier selection, contract negotiations, and ongoing supplier relationships.

Supplier performance metrics go beyond just assessing the quality of products or services provided by suppliers. They encompass a wide range of factors that contribute to the overall effectiveness and efficiency of the supply chain. These metrics take into account various aspects such as delivery time, responsiveness, reliability, cost-effectiveness, and compliance with regulatory requirements.

One of the key benefits of using supplier performance metrics is that they provide a standardized and objective way of evaluating suppliers. This eliminates biases and subjectivity that may arise from personal opinions or preferences. By using a consistent set of metrics, organizations can ensure that suppliers are assessed fairly and objectively, allowing for more accurate comparisons and evaluations.

The Role of Supplier Performance Metrics in Business

Supplier performance metrics play a vital role in the overall success of a business. They help monitor and manage supplier performance by measuring key performance indicators (KPIs) such as quality, delivery, and cost. These metrics enable organizations to assess supplier performance against predefined targets or benchmarks, identify areas of improvement, and take appropriate actions to enhance supplier performance.

By tracking supplier performance metrics, organizations can identify potential bottlenecks or areas of inefficiency in the supply chain. For example, if a supplier consistently fails to meet delivery deadlines, it may indicate issues with their production or logistics processes. By addressing these issues, organizations can improve the overall efficiency and reliability of their supply chain, ensuring timely delivery of products or services to customers.

Furthermore, supplier performance metrics provide valuable insights into the overall health and stability of the supply chain. By monitoring metrics such as on-time delivery and product quality, organizations can identify potential risks or vulnerabilities in their supply chain. This allows them to implement proactive measures to mitigate these risks, ensuring uninterrupted operations and customer satisfaction.

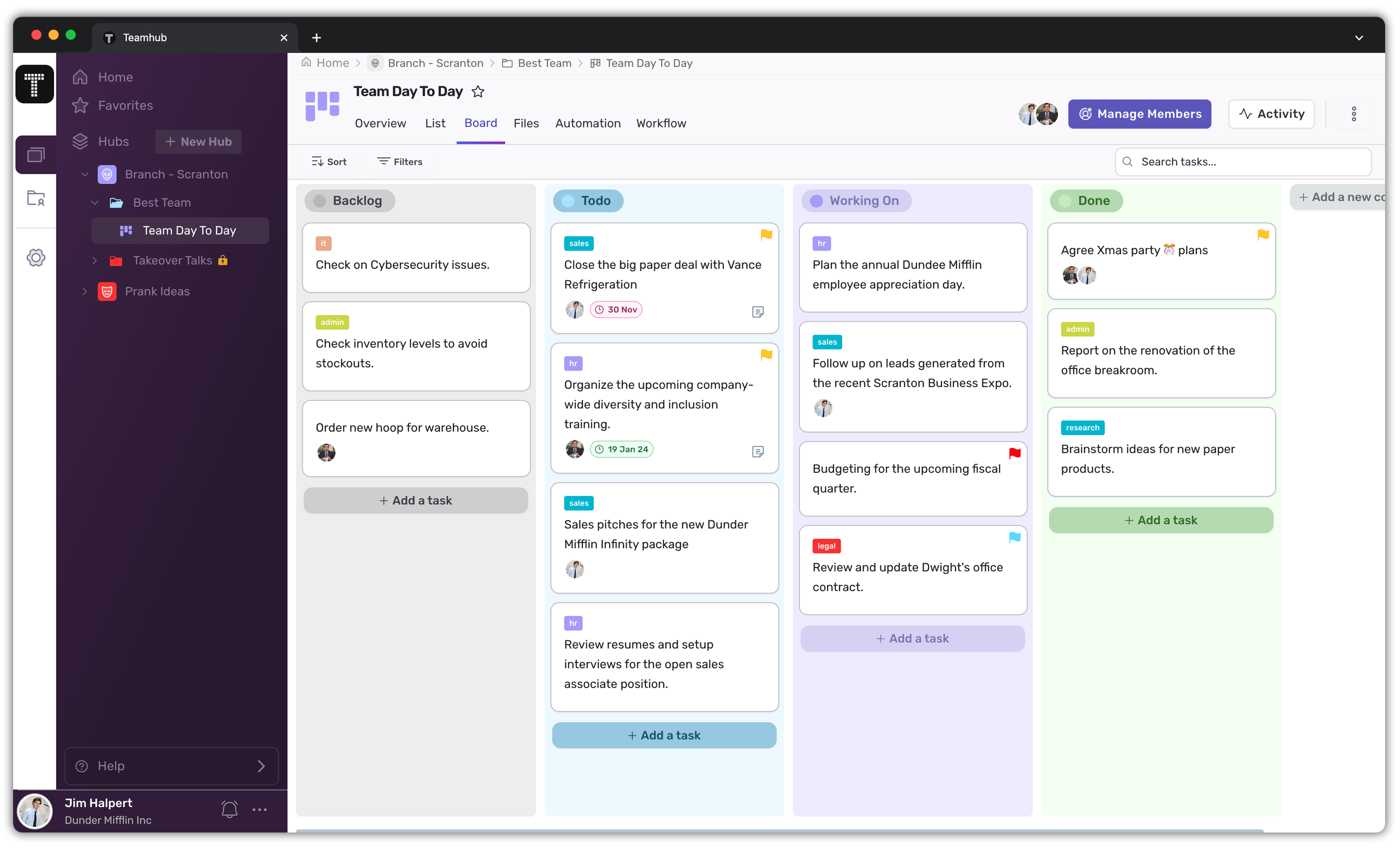

Unlock Efficiency with Teamhub

Key Benefits of Implementing Supplier Performance Metrics

The implementation of supplier performance metrics offers several benefits for businesses. Firstly, it helps drive supplier accountability by setting clear performance expectations and tracking supplier performance against those expectations. By establishing performance targets and regularly monitoring supplier performance, organizations can hold suppliers accountable for meeting agreed-upon standards.

Secondly, implementing supplier performance metrics enables organizations to identify high-performing suppliers. By analyzing supplier performance data, organizations can identify suppliers that consistently meet or exceed performance targets. This not only allows organizations to reward and recognize top-performing suppliers but also fosters stronger supplier relationships and encourages collaboration.

Additionally, supplier performance metrics facilitate risk management by identifying potential issues early on and allowing proactive measures to be taken. By monitoring metrics such as product quality or compliance with regulatory requirements, organizations can identify suppliers that may pose a higher risk of disruptions or non-compliance. This enables organizations to take necessary steps to mitigate these risks, such as diversifying their supplier base or implementing stricter quality control measures.

In conclusion, supplier performance metrics play a crucial role in supplier management and overall business success. By providing objective criteria for evaluating and comparing suppliers, these metrics enable organizations to make informed decisions, drive supplier accountability, foster stronger supplier relationships, and mitigate risks. Implementing supplier performance metrics is an essential step towards optimizing the supply chain and ensuring the delivery of high-quality products or services to customers.

Different Types of Supplier Performance Metrics

When it comes to evaluating supplier performance, organizations have a wide range of metrics at their disposal. These metrics can be categorized into different areas, each providing valuable insights into supplier performance. Let’s take a closer look at the various types of supplier performance metrics:

Quality Metrics for Suppliers

Ensuring high-quality products and services is crucial for any organization. To assess supplier quality, businesses can utilize a variety of metrics. One such metric is product defect rates, which measures the number of defective products received from a supplier. By tracking this metric, organizations can identify suppliers that consistently deliver subpar products, allowing them to make informed decisions about their partnerships.

Customer satisfaction scores are another important quality metric. By surveying customers and gathering feedback on their experiences with suppliers, organizations can gauge the level of satisfaction and identify areas for improvement. This metric not only helps in evaluating supplier performance but also provides valuable insights into customer preferences and expectations.

Adherence to specifications is yet another crucial quality metric. It measures how well suppliers comply with the specifications and requirements set by the organization. By monitoring this metric, businesses can ensure that suppliers consistently meet the desired standards, thereby maintaining product consistency and customer satisfaction.

Delivery Performance Metrics

Timely delivery is often a critical factor for organizations relying on suppliers to provide goods or services. To measure supplier punctuality and reliability, organizations can utilize delivery performance metrics. One such metric is the on-time delivery rate, which calculates the percentage of deliveries that arrive on or before the agreed-upon date. This metric helps organizations assess whether suppliers are meeting their delivery commitments and allows them to take appropriate actions if any issues arise.

Lead time is another important delivery performance metric. It measures the time it takes for a supplier to fulfill an order from the moment it is placed. By tracking lead time, organizations can identify suppliers that consistently deliver orders quickly and efficiently, ensuring a smooth flow of goods or services within the supply chain.

Cost Metrics in Supplier Performance

Managing costs is essential for organizations to maintain profitability and competitiveness. Therefore, evaluating cost metrics in supplier performance is crucial. One such metric is the cost savings achieved through supplier negotiations. By comparing the negotiated prices with the market prices, organizations can determine the extent to which they have been able to secure favorable terms with their suppliers.

Total cost of ownership is another important cost metric. It takes into account not only the purchase price of goods or services but also other costs associated with owning and using them. By considering factors such as maintenance costs, transportation costs, and potential risks, organizations can gain a comprehensive understanding of the true cost of working with a particular supplier.

Cost avoidance measures are also worth considering when evaluating supplier performance. These measures assess the extent to which suppliers have helped organizations avoid unnecessary costs. For example, a supplier that suggests alternative materials or processes that result in cost savings can be considered highly valuable.

By monitoring these cost metrics, organizations can identify opportunities for cost reduction, optimize supplier relationships, and enhance overall financial performance.

How to Measure Supplier Performance Metrics

Measuring supplier performance metrics requires a systematic approach to ensure accuracy and relevance. Organizations can follow a structured process to set up a robust supplier performance metrics system and regularly monitor and evaluate supplier performance.

Setting Up a Supplier Performance Metrics System

The first step in measuring supplier performance is to define the metrics that align with organizational goals and objectives. These metrics should be specific, measurable, achievable, relevant, and time-bound (SMART). Once the metrics are established, organizations need to communicate them to suppliers and ensure the necessary data collection mechanisms are in place.

Regular Monitoring and Evaluation of Supplier Performance

Regular monitoring and evaluation of supplier performance are essential for maintaining supplier accountability and driving continuous improvement. Organizations should establish a schedule for reviewing supplier performance, conduct performance evaluations, and communicate feedback to suppliers. This process allows organizations to track progress, address any performance issues promptly, and foster ongoing collaboration with suppliers.

Challenges in Implementing Supplier Performance Metrics

Although supplier performance metrics offer numerous benefits, implementing them can present challenges for organizations. Being aware of common obstacles and knowing how to overcome them is crucial for successful implementation.

Common Obstacles in Measuring Supplier Performance

One common challenge in measuring supplier performance is the lack of reliable and consistent data. Organizations may face difficulties in obtaining accurate information from suppliers, especially if data collection processes are not standardized. Another challenge is the reluctance of suppliers to share performance-related data, potentially due to concerns about confidentiality or competitive advantage.

Overcoming Challenges in Supplier Performance Metrics Implementation

To overcome these challenges, organizations can establish clear data reporting requirements in supplier contracts and agreements. They can also work closely with suppliers to identify mutually beneficial ways of collecting and sharing performance data. Additionally, leveraging technology solutions and implementing automated data capture systems can improve data accuracy and streamline the metrics reporting process.

Improving Supplier Performance through Effective Metrics

Implementing supplier performance metrics is only the first step. To drive meaningful improvements in supplier performance, organizations should implement strategies focused on enhancing supplier relationships and performance.

Strategies for Enhancing Supplier Performance

One effective strategy is to foster open communication and collaboration with suppliers. By establishing regular communication channels and sharing performance feedback, organizations can create an environment of transparency and continuous improvement. In addition, organizations can provide suppliers with training and resources to help them meet performance expectations and overcome any identified challenges.

The Future of Supplier Performance Metrics

As businesses continue to evolve, so too will the methods and importance of supplier performance metrics. The future of supplier performance metrics will likely involve the integration of advanced technologies, such as artificial intelligence and machine learning, to enhance data analysis and decision-making. Furthermore, organizations may explore new metrics that reflect evolving customer demands, sustainability goals, and social responsibility.

In conclusion, supplier performance metrics are essential tools that enable organizations to evaluate and improve the performance of their suppliers. By understanding the importance of these metrics, implementing the right measurement techniques, and overcoming common challenges, businesses can enhance their supplier relationships and drive better outcomes. Keeping pace with evolving trends and embracing future advancements will ensure that supplier performance metrics continue to play a key role in strategic supplier management.